Leading managers of western car manufacturers $STLAM (+4,18 %)

$GM (-2,18 %)

$F (+0,17 %)

$RIVN (+2,24 %) among others, are sounding the alarm in the face of growing competition from China.

From the "Big Three" in the USA to European corporations $VOW (+0,79 %)

$MBG (+0,09 %)

$BMW (+0,32 %) concerns are growing that Chinese manufacturers - including BYD $1211 (-4,65 %) - could become an existential threat in the long term.

Ahead of a hearing of the US House of Representatives, the Alliance for Automotive Innovation (AAI), which represents Ford, General Motors and Stellantis, among others, warned: "China poses a clear and imminent threat to the automotive industry in the US."

The association called on Congress to maintain existing import restrictions on certain Chinese technologies, which effectively limit market access for Chinese vehicles.

Rivian CEO RJ Scaringe points above all to the structural advantages of Chinese manufacturers. "It's not that the Chinese cost structure magically works. There are really two things that you can understand very clearly," Yahoo Finance quotes him as saying. Firstly, capital costs are "close to zero in most cases", as factories are heavily subsidized. Secondly, labor costs are only a quarter to a fifth of the US level. Tariffs would currently "even out" these differences, but only temporarily.

Ford boss Jim Farley also warns of the pace of development. "We are a year behind our Chinese competitors. They are now even more present worldwide," he said. In Europe, Chinese brands recently achieved a market share of around 6.1 percent - almost twice as much as in the previous year. Farley repeatedly referred to Chinese vehicles as an "existential threat" and emphasized: "They pose a major threat to the local workforce and receive huge subsidies from the government for their exports." He added: "As a country, we have to decide what is a fair playing field."

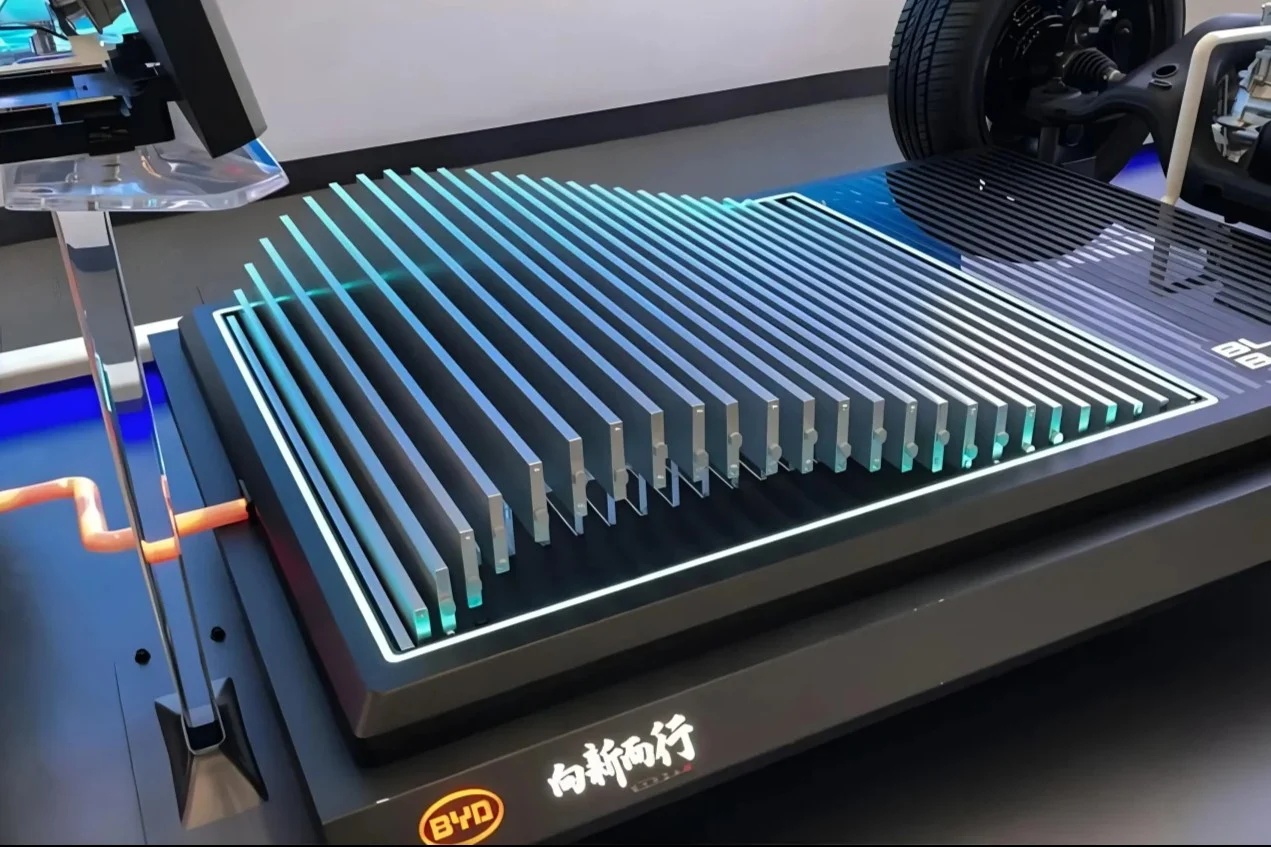

》Companies like BYD are exemplary of this rise《

The group is expanding aggressively in Europe and other markets and is benefiting from government support and vertically integrated supply chains, particularly for batteries.

Rivian CEO RJ Scaringe points above all to the structural advantages of Chinese manufacturers. "It's not that the Chinese cost structure magically works. It's really two things that you can understand very clearly," Yahoo Finance quotes him as saying.

Firstly, capital costs are "close to zero in most cases", as factories are heavily subsidized. Secondly, labor costs are only a quarter to a fifth of the US level.

Tariffs would currently "even out" these differences, but only temporarily (as with all other tariffs, mainly to the detriment of US citizens; in Europe, the tariffs already have little to no effect and are being replaced by European factories anyway 🤫😅)

Ford boss Jim Farley also warns of the pace of development. "We are a year behind our Chinese competitors (to put it charitably 😂). They are now even more globally present," he said.

In Europe, Chinese brands recently achieved a market share of around 6.1 percent - almost double that of the previous year. Farley repeatedly referred to Chinese vehicles as an "existential threat" and emphasized: "They pose a major threat to the local workforce and receive huge subsidies from the government for their exports." He added: "As a country, we have to decide what is a fair playing field."

Companies like BYD are exemplary of this rise. The group is aggressively expanding into Europe and other markets, benefiting from government support and vertically integrated supply chains, especially for batteries.

General Motors CEO Mary Barra also criticized Canada's decision to allow up to 49,000 electric vehicles to be produced in China each year. "I can't explain why this decision was made in Canada," she said and warned: "This is becoming a very dangerous development."

Pressure is also growing in Europe. Stellantis CEO Antonio Filosa and Porsche CEO Oliver Blume are calling for CO₂ incentives to be specifically linked to locally produced vehicles. "Europe is currently witnessing the emergence of new geopolitical rivalries," they wrote. "Trade, technology and industrial capacities are being mobilized more than ever to serve national interests. The European Union must choose a path quickly." (clearly they are already building in Europe and then the single market should be taxed 🤷🏻♂️🫣😂👍🏻)

Industry experts expect Chinese manufacturers to further accelerate their expansion in view of the saturation of their domestic market. For Western car manufacturers, this is not just about market share - but about the strategic future of their existence.

》Conclusion《

Whining at the highest level, first they all sleep through everything, then it's all about the money and then they wake up and whine about why nobody woke them up, that's how disenchantment with politics/lobbying works 🤷🏻♂️

The Chinese will literally overrun us, but cheers to the management, lobbying and, above all, the politicians who made this possible in the first place 🤫👍🏻😂