🇺🇸 USA

$SPX500 — Futures indicate a decisive surge, with the market attempting to recover losses from last week's banking sell-off.

$DJ30 — Futures in a solid rise, showing generalized risk-on sentiment.

$NSDQ100 — Futures are strongly up, with tech leading the market rebound.

💻 Tech & Growth Snapshot

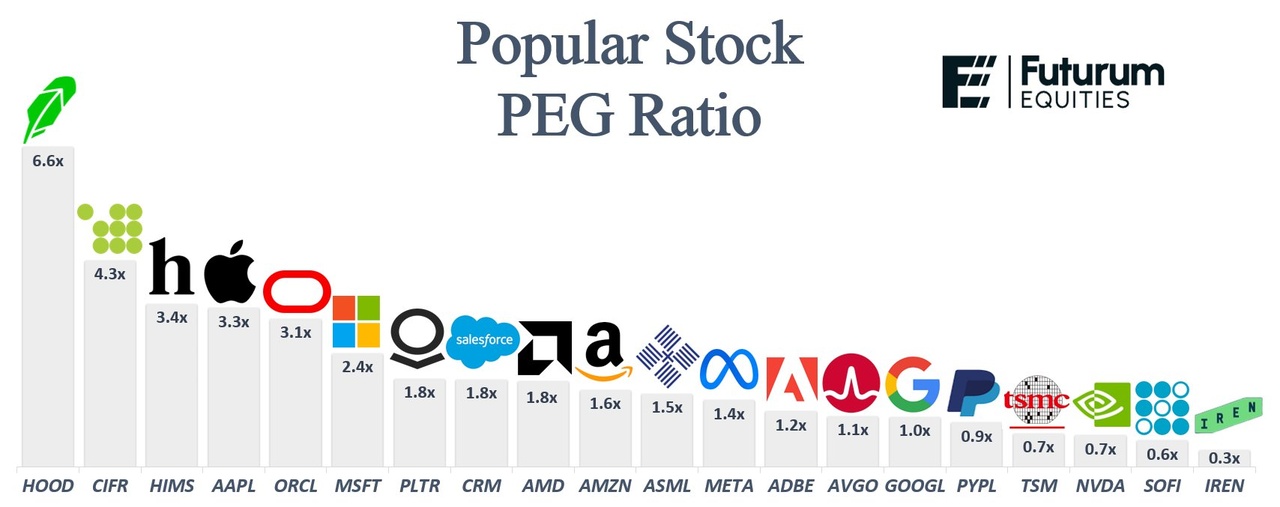

$NVDA (-0,1 %) — Up (0.55%), the stock is leading the semiconductor sector, confirming strong AI demand.

$GOOGL (+0,1 %) — Up (0.19%), the stock joins the positive Nasdaq trend.

$AVGO (+0,03 %) — Up (0.53%), the semiconductor sector benefits from renewed optimism.

$META (+0,33 %) — Up (0.48%), showing a strong recovery after recent weakness.

$MSFT (+0,03 %) — Up (0.36%), the stock regains momentum with positive sentiment.

$QBTS (+3,31 %) — Strongly up, quantum computing sentiment has turned positive amid the tech rebound.

$RGTI (+0,34 %) — Up sharply (3.08%), the quantum sector actively participates in the risk-on move.

$TSM (+2,27 %) — Up sharply (2.43%), boosted by optimism in the semiconductor sector.

🛍️ Retail & Commerce

$AMZN (-0,4 %) — Up (0.80%), strong pre-market recovery, led by tech.

$BABA (-0,42 %) — Down (-0.57%), counter-trending Western tech, affected by Asian uncertainties.

$CVNA (+1,32 %) — Up (0.57%), the stock gains ground following the broader market trend.

$SHOP (+1,09 %) — Solidly up, retail tech is driven by the general risk-on mood.

⚕️ Health & Pharmaceutical

$LLY (+0,08 %) — Up, tracking the general market rebound.

$HIMS (+3,17 %) — Stable (0.00%), the stock is steady after last week's volatility.

$INSM (+1,06 %) — Stable (0.00%), the biotech sector cautiously joins the rally.

🇪🇺 Europe

STOXX 600 — Opening solidly up, in line with global optimism.

GER40 — Decisively higher, the German market regains momentum.

$LDO (+2,79 %) — Stable (0.00%), the defense sector is neutral in this rebound phase.

$$IBE (+0,81 %) — Stable (0.00%), utilities are static in a risk-on environment.

$OKLO — Up sharply (1.73%), advanced nuclear technology continues its positive trend.

🏦 Banking & Finance

$$UCG (+1,16 %) — Stable (0.00%), Italian banks are trying to establish a base after heavy selling.

$$ISP (+1,12 %) — Stable (0.00%), awaiting clearer signals.

$$BAMI (+2,11 %) , $CE (+0,53 %) , $BPE (+2,99 %) — Stable (0.00%), the financial sector shows caution despite the risk-on trend.

$$BBVA (+2,61 %) — Stable (0.00%), the Spanish stock is leading the European banking recovery.

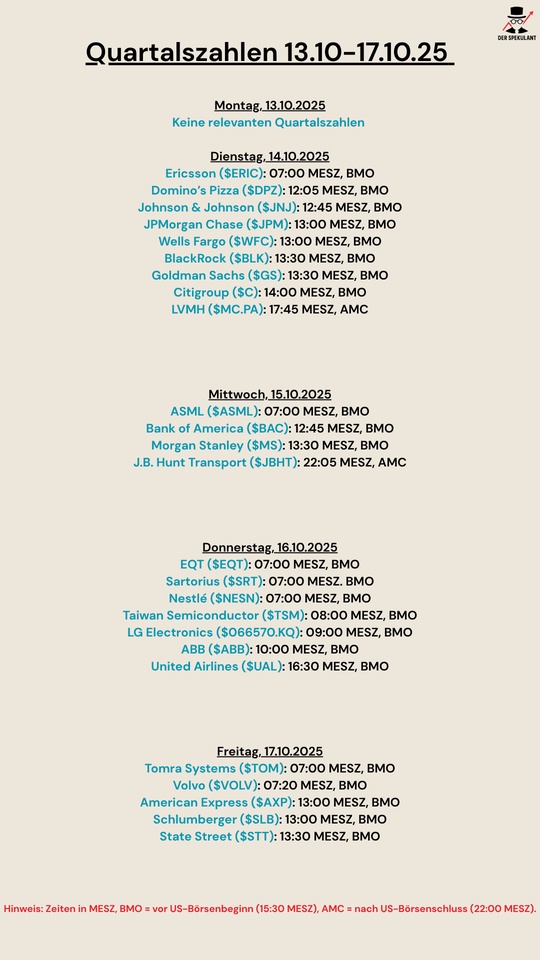

$AXP (+0,04 %) — Up (0.59%), the payments sector participates in the rebound.

$V (+0,09 %) — Up (0.07%), confirming its positive tone.

🌏 Asia

$JPN225 — Close in a solid rise, led by optimism in tech markets.

$KOSPI — Close up, Korean tech drives the index.

$HK50 — Up, tech stocks recover despite BABA's uncertainties.

$CHINA50 — Up, following positive global sentiment.

💱 Forex

$EURUSD — Up, the Dollar is losing momentum in a risk-on phase.

$GBPUSD — Up, the market positively assesses prospects for a stronger economy.

$USDJPY — Down, the Yen is gaining ground.

$DXY — The Dollar Index is showing clear weakness.

💎 Commodities & Precious Metals

$GLD (+0,28 %) — Down slightly (0.00%), gold consolidates as investors shift to riskier assets.

$CDE (+0,95 %) — Stable (0.00%), tracking the flat movement of gold.

$BRENT — Up, showing signs of demand recovery.

$WTI — Gaining ground, reflecting positive macroeconomic sentiment.

📈 Benchmark ETFs

$VOO (+0,29 %) — Tracking $SPX500$ futures higher.

$VGT (+0,54 %) — Up (0.00%), reflecting the strength of the technology sector.

$$CSNDX (+0,32 %) — Up (0.00%), tracking Nasdaq futures in positive territory.

$BND (-0,04 %) — Down (0.00%), reflecting rising yields.

💰 Crypto

$BTC (+1,87 %) — Strong recovery, the crypto sector bounces off the bottom and gains ground.

$ETH (+0,93 %) — Solidly up, following Bitcoin.

$TRX (+1,04 %) — Up (0.00%), the altcoin sector participates in the rally.

$CRO (+2,7 %) — Up, in line with overall positive sentiment.

🚀 Space & New Tech

$RKLB (+3,95 %) — Up, sentiment for growth stocks suggests a rebound.

🔎 Deep Dive: The Return of Risk-On

The week opens with a decisive "Risk-On" mood. Markets are clearly shrugging off (for now) last week's banking tensions, focusing instead on tech-led growth ($NVDA, $TSM$) and hopes for monetary easing. The strong rally in cryptocurrencies ($BTC, $ETH$) and the weakness of the Dollar ($DXY$) are clear indicators that liquidity is flowing back into riskier assets. European banks ($BBVA.MC$) and the semiconductor sector show unexpected strength, while gold ($GLD$) pauses, confirming the shift in focus from systemic risk to growth opportunities.

For daily real-time market insights, deep dives, and trading discussions, follow me on X: https://x.com/ThomasVioli

To copy my portfolio, strategies, and complete trade insights, you can follow me on eToro: https://www.etoro.com/people/farlys

⚠️ Disclaimer: Past performance is not indicative of future results. Investing involves risks, including the loss of capital.