After my first post on humanoid robots received a lot of positive feedback, I went into more detail. I have subsequently added my favorites in each sector.

Extended analysis of the value chain including shovel manufacturers and potential hidden champions

New categorySecondary key sectors (sales, marketing, financing)

In additionTop 25 companies worldwide, as well as Top 10 Europe and Top 10 Asia

I have also added a video link for beginners. This will give you an idea of how far the development of humanoid robotics has already progressed.

https://www.stern.de/panorama/wissen/humanoider-roboter---wie-reagiert-er-auf-beleidigungen--35996156.html

Thank you for your attention and your support 🙏

🌐 1. value chain of humanoid robots (with hidden champions)

1. research & chip design

$ARM (-4.91%) ARM (UK) - CPU-IP, energy-efficient processors

$SNPS (-1.03%) Synopsys (US) - EDA software, chip design

$CDNS (-0.81%) Cadence (US) - EDA & Simulation

$PTC PTC (US) - Engineering Software, CAD/PLM

$DSY (+0.94%) Dassault Systèmes (FR) - 3D Design & Digital Twin

$SIE (-0.81%) Siemens (DE) - Industrial Software & Lifecycle Mgmt

$ADBE (+0.44%) Adobe (US) - Design, AR/UX

ANSYS (US) - multiphysical simulation - acquisition by Synopsis

Altair (US) - CAE, simulation, digital twin - acquisition by Siemens

$HXGBY (-1.08%)

Hexagon (SE) - Metrology & Simulation

$AWE Alphawave IP Group (UK) - High-speed chip IP for AI/robotics

1.Synopsis, 2.Siemens and 3.Adobe are my top 3 in this sector

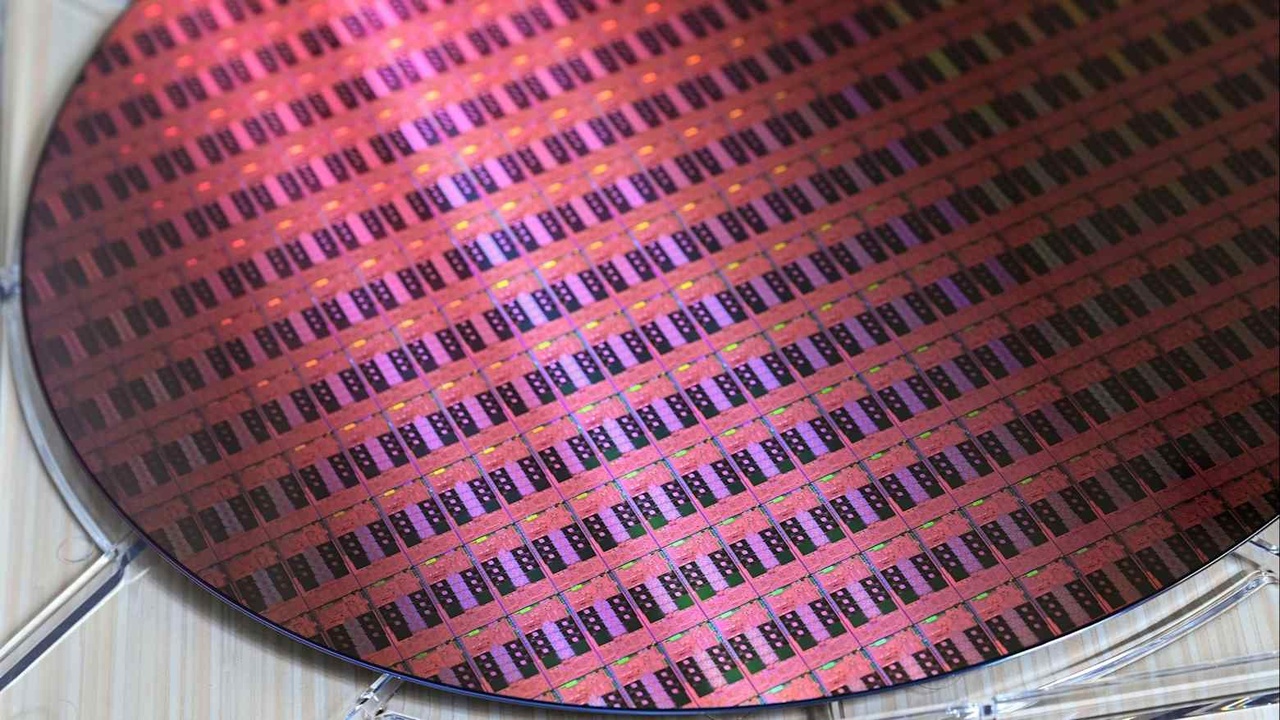

2. manufacturing technology & equipment

$ASML (-5.28%) ASML (NL) - Lithography (EUV)

$AMAT (-5.5%) Applied Materials (US) - Semiconductor equipment

$8035 (-1.58%) Tokyo Electron (JP) - wafer fabrication

$KEYS (-4.31%) Keysight Technologies (US) - Metrology

$6857 (-1.72%) Advantest (JP) - Chip test systems

$TER (-10.17%) Teradyne (US) - test systems + cobots

$6954 (-2.46%) Fanuc (JP) - Industrial robots, CNC

$CAT (-3.78%) Caterpillar (US) - autonomous machines

$KU2G KUKA (DE) - industrial robots

Comau (IT) - automation - not listed on the stock exchange

$ROK Rockwell Automation (US) - industrial automation

$JBL (-4.35%) Jabil (US) - contract manufacturing (EMS/ODM)

$KIT (-4.46%) Kitron (NO) - European EMS/ODM manufacturer

$AIXA (-4.81%) Aixtron (DE) - deposition equipment for compound semiconductors

$LRCX (-6.63%)

Lam Research (US) - Etch/deposition systems

$MKSI (-8.58%)

MKS Instruments (US) - Plasma/vacuum technology

$ASM (-9.18%)

ASM International (NL) - Deposition systems

1.ASML, 2.Keysight Technologies, 3.Fanuc are my top 3 in this sector

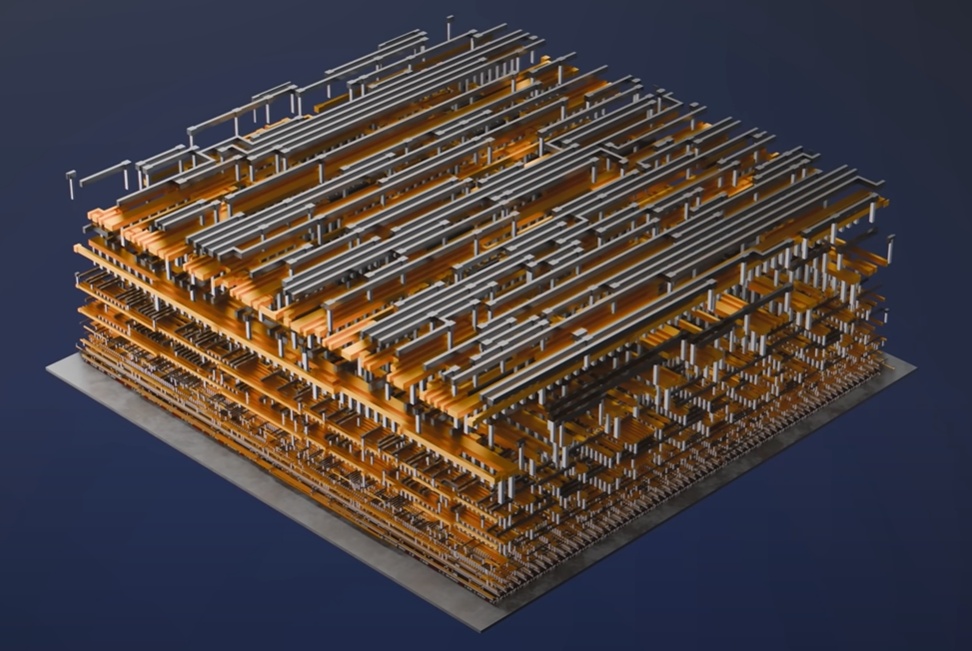

3. chip manufacturing (foundries)

$TSM (-4.34%) TSMC (TW) - leading foundry

$SMSN Samsung Electronics (KR) - foundry + memory

$GFS (-5.66%) GlobalFoundries (US) - specialty chips

$INTC (-5.24%)

Intel Foundry Services (US) - new western foundry player

$981

SMIC (CN) - largest Chinese foundry

$UMC (-3.5%)

UMC (TW) - Power/RF/Embedded chips

1.TSMC, 2.Intel, 3.Samsung Electronics are my top 3 in this sector

4. computing & control unit ("brain")

$NVDA (-2.56%) Nvidia (US) - GPUs, AI chips

$INTC (-5.24%) Intel (US) - CPUs, FPGAs

$AMD (-3.16%) AMD (US) - CPUs, GPUs

$MRVL (+6.33%) Marvell (US) - Network Chips

$MU (-5.88%) Micron (US) - Memory

$DELL (+0.16%) Dell Technologies (US) - Edge & Infrastructure

Graphcore (UK) - AI chips (IPU) - not a listed company

Cerebras (US) - Wafer-scale engine - not a listed company

SiPearl (FR) - European HPC chip - not a listed company

1.Nvidia, 2.Marvell, 3.Micron are my top 3 in this sector

5. sensors ("senses")

$6758 (+1.22%) Sony (JP) - image sensors

$6861 (+0.01%) Keyence (JP) - Industrial sensors

$STM (-7.51%) STMicroelectronics (FR/IT) - Sensors, MCUs

$TDY Teledyne (US) - optical/infrared sensors

$CGNX (-3.58%) Cognex (US) - Machine Vision

$HON (-1.78%) Honeywell (US) - sensor technology, security

ANYbotics (CH) - autonomous sensor fusion - not a listed company

$AMBA (-5.34%) Ambarella (US) - video & computer vision SoCs for real-time image recognition

$OUST

Velodyne Lidar (US) - Lidar sensors - acquisition by Ouster

$AMS (-1.57%)

OSRAM (AT/DE) - optical sensors

1.Teledyne, 2.Keyence, 3.Ouster are my top 3 in this sector

6. actuators & power electronics ("muscles")

$IFX (-7.39%) Infineon (DE) - Power Electronics

$ON (-6.58%) onsemi (US) - Power & Sensors

$TXN (-2.62%) Texas Instruments (US) - Mixed-Signal Chips

$ADI (-4.3%) Analog Devices (US) - Signal Processing

$PH Parker-Hannifin (US) - Hydraulics/Pneumatics

$MP (-5.64%) MP Materials (US) - Magnets

$APH (-2.62%) Amphenol (US) - Connectors

$6481 (-0.36%) THK (JP) - Linear guides & actuators

$6324 (-8.54%)

Harmonic Drive (JP) - Precision gears & servo drives for robotics

$6594 (-2.79%)

Nidec (JP) - Electric motors

$6506 (-1.93%)

Yaskawa (JP) - Drives & Robotics

$SU (-2.9%)

Schneider Electric (FR) - Energy & control solutions

$ZIL2 (+1.59%)

ElringKlinger (DE) - Battery & fuel cell technology, lightweight construction

1.Parker-Hannifin, 2.MP Materials, 3.Infinion are my top 3 in this sector

7. communication & networking ("nerves")

$QCOM (-1.01%) Qualcomm (US) - mobile communications, edge AI

$ANET (-4.24%) Arista Networks (US) - Networks

$CSCO (-1.86%) Cisco (US) - Networks, Security

$EQIX (-2.46%) Equinix (US) - Data centers

NTT Docomo (JP) - 5G/6G carrier - not a listed company

$VZ Verizon (US) - Telecommunications

$SFTBY SoftBank (JP) - Carrier + Robotics

$ERIC B (-2.18%)

Ericsson (SE) - 5G/IoT infrastructure

$NOKIA (-2.15%)

Nokia (FI) - 5G/6G for industry

$HPE (-1.25%)

Juniper Networks (US) - Network technology - acquisition by HP

1.Arista Networks, 2.SoftBank, 3.Cisco are my top 3 in this sector

8. energy supply

$3750 (+1.65%) CATL (CN) - Batteries

$6752 (-0.62%) Panasonic (JP) - Batteries

$373220 LG Energy (KR) - Batteries

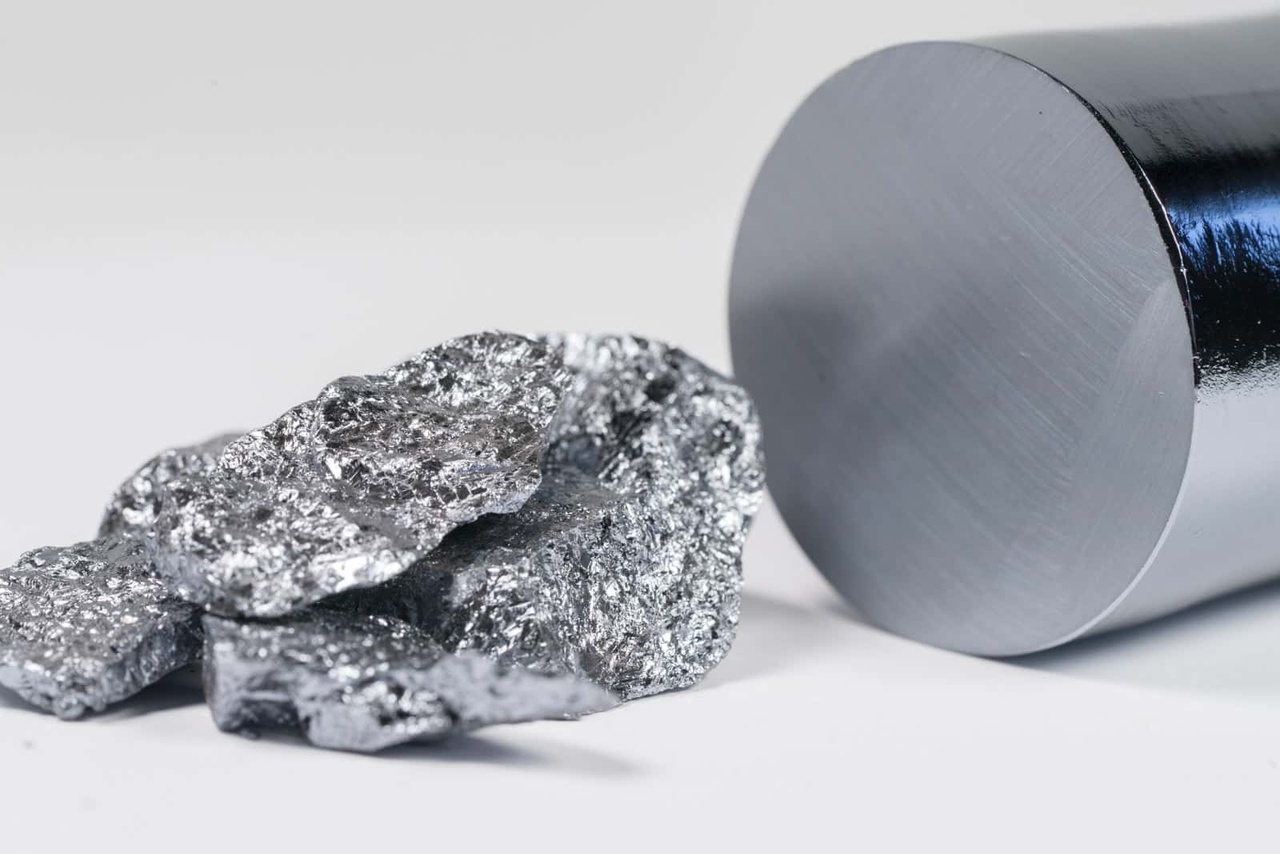

$ALB (-1.84%) Albemarle (US) - Lithium

$LYC (-1.38%) Lynas (AU) - Rare earths

$UMICY (-4.56%) Umicore (BE) - recycling

WiTricity (US) - inductive charging - not a listed company

$ABBN (+0.72%) Charging (CH) - charging infrastructure

$SLDP

Solid Power (US) - Solid state batteries

Northvolt (SE) - European batteries - not a listed company

$PLUG (-7.14%)

Plug Power (US) - fuel cells

$KULR (-6.54%)

KULR Technology (US) - Thermal management & battery safety for mobile systems

1.Albemarle, 2.CATL, 3.Panasonic are my top 3 in this sector

9. cloud & infrastructure

$AMZN (-2.34%) Amazon AWS (US) - Cloud, AI

$MSFT (-0.48%) Microsoft Azure (US) - Cloud, AI

$GOOG (-0.74%) Alphabet Google Cloud (US) - Cloud, ML

$VRT

Vertiv Holdings (US) - Data center infrastructure (UPS, cooling, edge)

$ORCL (-2.6%)

Oracle Cloud (US) - ERP + Cloud

$IBM (+0.64%)

IBM Cloud (US) - Hybrid cloud + AI

$OVH (+1.15%)

OVHcloud (FR) - European cloud

1.Alphabet, 2.Microsoft, 3.Oracle are my top 3 in this sector

10. software & data platforms

$PLTR (+2.91%) Palantir (US) - Data integration

$DDOG (+2.85%) Datadog (US) - Monitoring

$SNOW (+1.78%) Snowflake (US) - Data Cloud

$ORCL (-2.6%) Oracle (US) - Databases, ERP

$SAP (+0.58%) SAP (DE) - ERP systems

$SPGI S&P Global (US) - financial/market data

ROS2 Foundation - robotics middleware - not listed on the stock exchange

$NVDA (-2.56%) NVIDIA Isaac (US) - robotics development - part of Nvidia

$INOD (-0.68%) Innodata (US) - data annotation & AI training data

$PATH (+2.83%)

UiPath (RO/US) - Robotic process automation

$AI (-2.47%)

C3.ai (US) - AI platform

$ESTC (-0.22%)

(NL/US) - Search & data analysis

1.S&P Global, 2.Palantir, 3.Datadog are my top 3 in this sector

11. end applications / robots

$ABBN (+0.72%) ABB (CH/SE) - Industrial Robots

$6954 (-2.46%) Fanuc (JP) - Industrial robots

$TSLA (-2.04%) Tesla Optimus (US) - humanoid robot

$9618 (+6.18%) JD.com (CN) - logistics robot

$AAPL (-1%) Apple (US) - Platform & UX

$700 (+1.49%) Tencent (CN) - Platform & AI

$9988 (+1.04%) Alibaba (CN) - logistics & platform

PAL Robotics (ES) - humanoid robots - not a listed company

Neura Robotics (DE) - cognitive humanoid robots - not a listed company

$TER (-10.17%) Universal Robots (DK) - cobots - belongs to the Teradyne Corporation

Engineered Arts (UK) - humanoid robots - not a listed company

$ISRG (-1.23%) Intuitive Surgical (US) - surgical robotics

$GMED (-4.47%)

Globus Medical (US) - surgical robotics (ExcelsiusGPS platform)

$7012 (-3.94%) Kawasaki Heavy Industries (JP) - industrial robots, automation

$CPNG (-1.78%) Coupang (KR) - Logistics end user

$IRBT

iRobot (US) - consumer robotics (e.g. Roomba), non-humanoid, but navigation/sensor fusion

Boston Dynamics (US) - humanoid & mobile robots-no listed company

Hanson Robotics (HK) - humanoid robots (Sophia) - not a listed company

Agility Robotics (US) - humanoid robot "Digit" - not a listed company

1.Apple, 2.Tencent, 3.Alibaba are my top 3 in this sector

🛠 2. cross enablers (shovel manufacturers) - with hidden champions

Raw materials & battery materials

Albemarle - Lynas - Umicore

$SQM

SQM (CL) - Lithium

$ILU (-1.06%)

Iluka Resources (AU) - Rare earths

$ARR (-0.23%)

American Rare Earths (US/AU) - New supply chains

my number 1 in the sector is Albemarle

manufacturing technology

ASML - Applied Materials - Tokyo Electron

$LRCX (-6.63%)

Lam Research (US) - Plasma/etching processes

$ASM (-9.18%)

ASM International (NL) - ALD equipment

$MKSI (-8.58%)

MKS Instruments (US) - Plasma/vacuum technology

my number 1 in the sector is ASML

Quality assurance

Keysight - Advantest - Teradyne

$EMR (-2.84%)

National Instruments (US) - Measurement technology - from Emerson Electric adopted

$300567

ATE Test Systems (CN) - test systems

$FORM (-7.86%)

FormFactor (US) - Wafer probing

my number 1 in the sector is Keysight

Motion & Drive

Parker-Hannifin

Festo (DE) - Pneumatics, Soft Robotics - not a listed company

Bosch Rexroth (DE) - Drives, Controls - not a listed company

$6481 (-0.36%)

THK (JP) - Linear guides

my number 1 in the sector is Parker-Hannifin

Sensors/Imaging

$TDY Teledyne

$BSL (-0.4%) Basler (DE) - Industrial cameras

FLIR (US) - Thermal imaging sensors - acquisition by Teledyne

ISRA Vision (DE) - Machine Vision - not a listed company

my number 1 in the sector is Teledyne

Magnets & Materials

MP Materials

$6501 (-2.35%)

Hitachi Metals (JP) - Magnetic materials

VacuumSchmelze (DE) - Magnetic materials - not a listed company

$4063 (-1.33%)

Shin-Etsu Chemical (JP) - Specialty materials

my number 1 in the sector is MP Materials

Chip Design & Simulation

Synopsys - Cadence - ARM

$SIE (-0.81%)

Siemens EDA (DE/US)-Mentor Graphics-strategic business unit of Siemens AG

Imagination Tech (UK) - GPU-IP - not a listed company

$CEVA (-7.32%)

CEVA (IL) - Signal Processor IP

my number 1 in the sector is Synopsys

Engineering & Lifecycle

PTC - Dassault - Siemens

Altair (US) - Simulation - no longer a listed company

$HXGBY (-1.08%)

Hexagon (SE) - Metrology

$SNPS (-1.03%)

ANSYS (US) - Simulation - takeover by Synopsys

my number 1 in the sector is Siemens

Networks & Data Centers

Arista - Cisco - Equinix

$HPE (-1.25%)

Juniper (US) - Networks - Acquisition of HPE

$DTE (-0.64%)

T-Systems (DE) - Industry cloud

$OVH (+1.15%)

OVHcloud (FR) - European cloud

my number 1 in the sector is Arista

Cloud infrastructure

AWS - Azure - Google Cloud

$ORCL (-2.6%)

Oracle Cloud (US) - ERP & databases

$IBM (+0.64%)

IBM Cloud (US) - Hybrid Cloud

$9988 (+1.04%)

Alibaba Cloud (CN) - Asian Cloud

$VRT

Vertiv Holdings (US) - Cloud/Infra

my number 1 in the sector is Alphabet (Google)

finance/information infra

S&P Global

$MCO (-1.18%)

Moody's (US) - Ratings

$MSCI (+0.47%)

MSCI (US) - Indices

$MORN

Morningstar (US) - Investment Research

my number 1 in the sector is S&P Global

Creative/Experience Infra

Adobe

$ADSK (-1.25%)

Autodesk (US) - CAD & Design

$U

Unity (US) - 3D/AR simulation

Epic Games (US) - Unreal Engine - not a listed company

my number 1 in the sector is Adobe

Platform & Ecosystem

Apple - Tencent - Alibaba

$META (-2.49%)

Meta (US) - AR/VR, Social Robotics

ByteDance (CN) - AI & platforms - not a listed company

$9888 (-0.63%)

Baidu (CN) - AI & Cloud

my number 1 in the sector is Tencent

Infrastructure/Edge

Dell

$HPE (-1.25%)

HPE (US) - Edge Computing

$SMCI

Supermicro (US) - AI servers

$6702 (+4.73%)

Fujitsu (JP) - Edge & HPC

my number 1 in the sector is Dell

storage solutions

Micron

$HY9H

SK Hynix (KR) - Memory

$285A (-5.83%)

Kioxia (JP) - NAND

$WDC

Western Digital (US) - Storage solutions

my number 1 in the sector is Micron

🏛 3. secondary key sectors with hidden champions

Financing & Capital

$GS (-1.79%) Goldman Sachs (US) - investment bank; ECM/DCM, M&A, growth financing

$MS Morgan Stanley (US) - investment bank; tech banking, capital markets

$BLK (-8.13%) BlackRock (US) - asset manager; capital allocation, ETFs/index funds

$9984 (-3.24%) SoftBank Vision Fund (JP) - mega VC; growth equity in robotics/AI

Sequoia Capital (US) - venture capital; early/growth in AI/robotics - this is a classic venture capital fund

DARPA (US) - government R&D funding (robotics/defense) - independent research and development agency

EU Horizon (EU) - research funding/grants for DeepTech - Innovative Europe pillar

China State Funds (CN) - state industry/technology fund

Lux Capital (US) - VC for DeepTech - Uptake (US) - AI-based predictive maintenance

DCVC (US) - Robotics & AI focus - investing exclusively via VC fund investments

Speedinvest (AT) - EU VC for robotics - access to investment only via fund investments

my number 1 in the sector is Softbank

Maintenance & Service

$SIE (-0.81%) Siemens (DE) - Industrial Service, Lifecycle & Retrofit

$ABBN (+0.72%) ABB (CH/SE) - Robotics Service, Spare Parts, Field Support

$GEHC (-2.81%) GE Healthcare (US) - Medtech service incl. robotic systems

Uptake (US) - AI-based predictive maintenance - not a listed company

Augury (US/IL) - condition monitoring, condition diagnostics - not a listed company

$KU2 KUKA Service (DE) - Robotics maintenance

$6954 (-2.46%) Fanuc Service (JP) - global service network

Boston Dynamics AI Institute (US) - Robotics longevity - funded by Hyundai Motor Group

my number 1 in the sector is Siemens

Marketing & Advertising

$WPP (-1.93%) WPP (UK) - global advertising group; branding/communications

$OMC Omnicom (US) - marketing/PR network

$PUB (+0.12%) Publicis (FR) - communications/advertising group

$META (-2.49%) Meta (US) - Digital Ads (Facebook/Instagram)

$GOOG (-0.74%) Google Ads (US) - search & display advertising

TikTok / ByteDance (CN) - social ads & distribution - not a listed company

$AAPL (-1%) Apple (US) - Branding/UX; Acceptance & Platform Marketing

$WPP (-1.93%)

AKQA (UK/US) - Tech branding - Since 2012 majority owned by the WPP Groupbut continues to operate as an autonomous operating unit

R/GA (US) - Innovation marketing - not a listed company

Serviceplan (DE) - largest independent EU agency - not a listed company

my number 1 in the sector is Meta

Law, Regulation & Ethics

ISO (CH) - international standards, robotics standards

TÜV (DE) - certification & safety tests

UL (US) - safety/conformity testing

EU AI Act (EU) - legal framework for AI & robotics

UNESCO AI Ethics (UN) - global ethics guidelines

Fraunhofer IPA (DE) - Robotics safety standards

ANSI (US) - standards

IEC (CH) - Electrical engineering standards

Training & Talent

MIT (US) - Robotics/AI Research & Education

ETH Zurich (CH) - autonomous systems & robotics

Stanford (US) - AI/Robotics labs & spin-offs

Tsinghua University (CN) - Robotics/AI in Asia

CMU (US) - Robotics Institute

EPFL (CH) - Robotics research

TU Munich (DE) - humanoid robot "Roboy"

🌍 Top 25 companies for humanoid robotics

These companies are central to the development & production of humanoid robotsbecause without them, crucial parts of the chain would be missing:

Chips & computing power (brain of the robots)

$NVDA (-2.56%) Nvidia (US) - AI GPUs & Isaac platform, foundation for robotic AI

$2330 TSMC (TW) - world's most important foundry, produces the AI chips

$ASML (-5.28%) ASML (NL) - EUV lithography, indispensable for chip production

$005930 Samsung Electronics (KR) - memory, logic, foundry

$HY9H SK Hynix (KR) - DRAM & NAND memory for AI

$MU (-5.88%) Micron (US) - Memory solutions for AI workloads

my number 1 in the sector is ASML

Sensors & perception (senses of robots)

$SONY Sony (JP) - image sensors, market leader

$6861 (+0.01%) Keyence (JP) - Industrial sensors & vision systems

$CGNX (-3.58%) Cognex (US) - Machine Vision, precise image processing

my number 1 in the sector is Keyence

Actuators & motion (muscles of robots)

$IFX (-7.39%) Infineon (DE) - power electronics, motor control

$6594 (-2.79%) Nidec (JP) - World market leader for electric motors

$PH Parker-Hannifin (US) - hydraulics/pneumatics, motion technology

$6481 (-0.36%) THK (JP) - Linear guides & actuators

my number 1 in the sector is Parker-Hannifin

Communication, cloud & infrastructure (nerves & data flow)

$QCOM (-1.01%) Qualcomm (US) - Mobile & Edge Chips

$AMZN (-2.34%) Amazon AWS (US) - Cloud & AI infrastructure

$MSFT (-0.48%) Microsoft Azure (US) - Cloud, AI services

$CSCO (-1.86%) Cisco (US) - Networks & Security

$VRT Vertiv Holdings (US) - Data Center Infrastructure

my number 1 in the sector is Microsoft

End Applications & Platforms (robots themselves)

$TSLA (-2.04%) Tesla (US) - humanoid robot Optimus

$ABBN (+0.72%) ABB (CH/SE) - Robotics & Automation

$6954 (-2.46%) Fanuc (JP) - industrial robots & CNC systems

$7012 (-3.94%) Kawasaki Heavy Industries (JP) - industrial robots

PAL Robotics (ES) - humanoid robots (TALOS, ARI, TIAGo) - not a listed company

Neura Robotics (DE) - cognitive humanoid robots - not a listed company

Universal Robots (DK) - cobots

my number 1 in the sector is Tesla

🇪🇺 Top 10 European key companies for humanoid robotics

$ASML (-5.28%)

ASML (NL)

World market leader in EUV lithography - no modern chips for AI & robotics without ASML.

$IFX (-7.39%) Infineon (DE)

Leading in power electronics & motor control - crucial for actuators of humanoid robots.

$STM (-7.51%)

STMicroelectronics (FR/IT)

Sensors, microcontrollers & power chips - the basis for control & perception.

$SAP (+0.58%)

SAP (DE)

ERP & data platforms, important for integrating humanoid robots into industrial processes.

$SIE (-0.81%)

Siemens (DE)

Industrial software, automation, digital twin - key for engineering & lifecycle management.

$KU2 KUKA (EN)

Robotics pioneer, industrial robots & automation - know-how for humanoid motion mechanics.

PAL Robotics (ES) - not a listed company

Specialist for humanoid robots (TALOS, ARI, TIAGo), internationally used in research & service.

Neura Robotics (DE) - Not a listed company

Young high-tech company, develops cognitive humanoid robots with advanced AI (4NE-1).

Universal Robots (DK) - Not a listed company

Market leader for cobots - platform for safe human-robot collaboration.

Engineered Arts (UK) - not a listed company

Develops humanoid robots such as Amecaknown for realistic facial expressions & gestures - important for HRI (Human-Robot Interaction)

🌏 Top 10 Asian key companies for humanoid robotics

$2330

TSMC (Taiwan)

World's largest semiconductor foundry, produces high-end chips (e.g. Nvidia, AMD, Apple) - no AI hardware without TSMC.

$005930

Samsung Electronics (South Korea)

Foundry, memory, logic chips, image sensors - extremely broadly positioned in robotics components.

$HY9H

SK Hynix (KR) - Memory

$SONY

Sony (Japan)

Market leader in CMOS image sensors, essential for robotic vision & perception.

$6861 (+0.01%)

Keyence (Japan)

Sensor technology & machine vision for industrial automation, widely used in robotics.

$6954 (-2.46%)

Fanuc (Japan)

Industrial robots & CNC systems, one of the most important manufacturers of robotics hardware worldwide.

$6506 (-1.93%)

Yaskawa Electric (Japan)

Drives, motion control & robot arms - relevant for humanoid motion control.

$6594 (-2.79%)

Nidec (Japan)

World market leader for electric motors (from mini motors to high-performance drives).

$7012 (-3.94%)

Kawasaki Heavy Industries (JP) - Industrial robots

$9618 (+6.18%)

JD.com (China)

Driver for robotics in e-commerce & logistics, invests in humanoid robotics applications