The Chinese car and battery manufacturer BYD $1211 (-2,98 %) reports progress with new types of batteries that could make electric cars cheaper in the future.

This involves the third-generation sodium-ion platform on the one hand and sulphide solid-state batteries on the other.

Even though BYD is primarily known as an e-car manufacturer, the Shenzhen-based company is also the second largest battery producer in the world behind CATL $3750 (+1,7 %)

According to market researcher SNE Research, BYD achieved an annual production of 194.8 GWh last year - 27.7 percent more than in 2024.

In order to remain at the top, BYD also maintains large research facilities for batteries, which have now reached important milestones.

On the one hand, this involves sodium-ion batteries, which are expected to bring about a clear cost reduction in the e-car sector. After all, the inexpensive sodium is replacing lithium, which has become very expensive.

However, sodium-ion batteries are known to have a lower energy density - and this is the challenge that BYD and other suppliers have to overcome.

The company is now said to be pressing ahead with the development of its third-generation sodium-ion platform. The technology is expected to enable up to 10,000 charging cycles, with the market launch depending on customer demand and deployment plans, as reported by Car News China.

This would be significantly more than with conventional LFP batteries, which manage 2,000 to 3,000 charging cycles. However, there is no further information on the specifications of the sodium-ion battery - and therefore also not on the important energy density.

What is known, however, is that BYD has already started building its first factory for sodium-ion batteries in Xuzhou at the beginning of 2024, which it intends to operate together with Huaihai, a manufacturer of electric two- and three-wheelers.

On the other hand, BYD is working on a sulfide solid-state battery and has apparently achieved important improvements here too, even if these are not disclosed in detail.

The sulphide solid-state battery is said to have the potential for ground-breaking advances in battery life and fast-charging capability and thus represents an important technological innovation.

Based on the current state of research and development, BYD expects to be able to produce its sulfide solid-state batteries on a small scale by 2027.

Solid-state batteries replace the liquid electrolyte with a solid one, which can improve safety, energy density and service life.

BYD is focusing on sulphide-based solid-state electrolytes as they promise high ionic conductivity and good processability. As Sun Huajun, CTO of the battery business, reported at an event in early 2025, the company has already produced its first solid-state cells with 20 Ah and 60 Ah on its pilot production line in 2024.

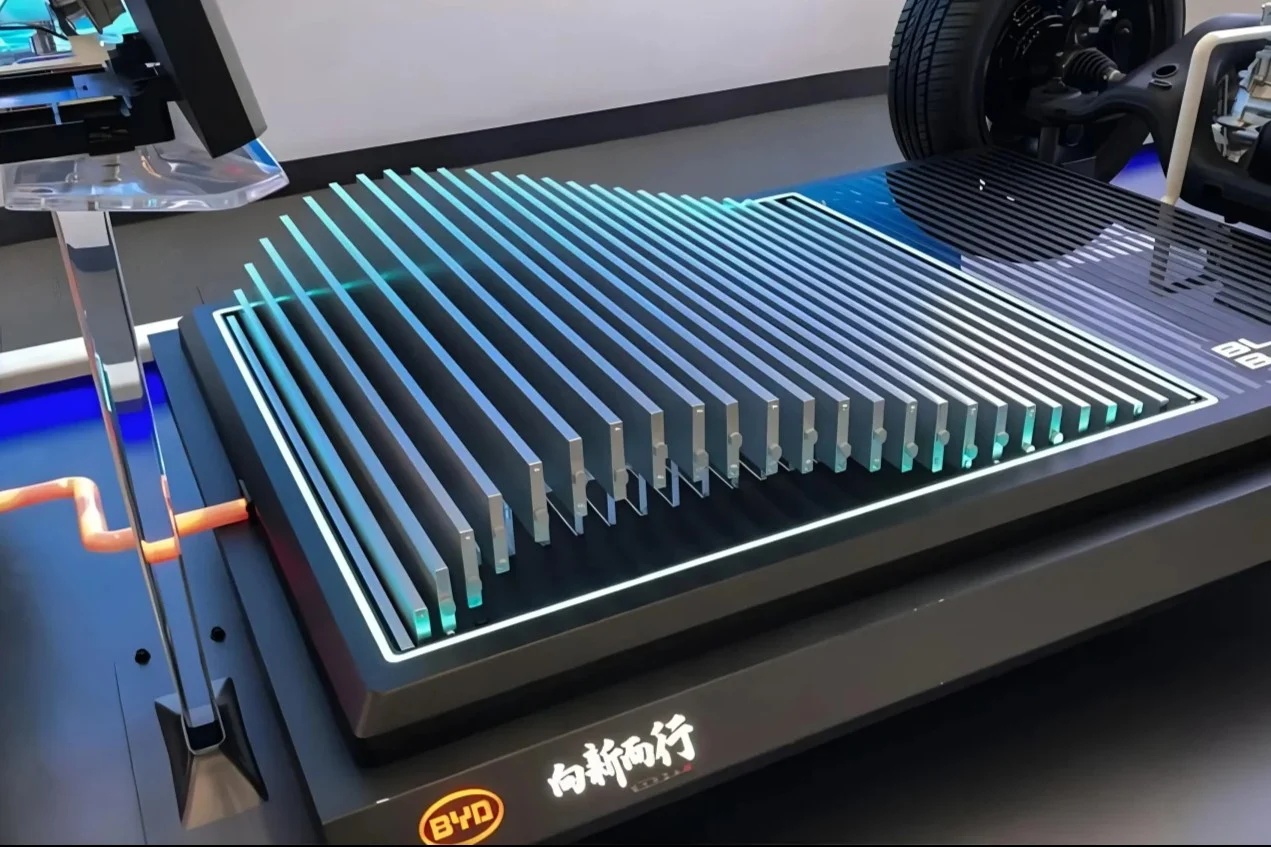

BYD is currently best known for its blade batteries with LFP cell chemistry.

These lithium iron phosphate cells are considered to be more robust and cheaper than cell chemistries based on nickel and cobalt, but generally have a lower energy density.

It must therefore be assumed that BYD will pursue several technology paths in the future - and will continue to serve the mass market with LFP batteries, while sodium and solid-state batteries will initially only be used in selected applications.